After deciding on a concrete block building approach, my research turned to the engineering side of the construction and to make sure that what I am about to undertake will stand the test of time and not just end up a big hole in the group…

I will post up at some point some really helpful websites, but the following is an extract of all of the advice that I have taken from them in the design of my pool.

The pool will be submerged (i.e. not above ground) and therefore some special considerations need to be made. The first of which is ground water… Whilst it is hard to believe, if you have enough ground water, it can lift an empty concrete pool out of the ground (see image below for an extreme example).

Therefore it is important to place a peripheral drain in the bottom and a means of evacuation (i.e. decompression well with sump pump).

The following picture illustrates the layers that need to be built up in the pool, following the earthworks. They are, from bottom up:

- Geotextile membrane

- Gravel bed

- Peripheral drain

- Polythene membrane

- Concreate slab

- Walls and back-fill

Most research suggest that a gravel bed of 0/20 (Type 1) gravel to a depth of 10-20cm is sufficient. The depth is ultimately determined by the soil conditions. We fortunately live in a very rocky part of France, so should have good stable conditions.

Next thing to consider is the concrete slab, which should again be 15-20cm in depth and reinforced using welded steel mesh. The diagram shows the typical reinforcements required in a pool less than 10x5m.

Some things to note in particular are:

- At least 30mm distance between any steel reinforcements and the exterior (top, bottom, and sides) of the concrete slab – otherwise water can penetrate, rust the steel, and compromise the structural integrity of the slab

- ST25C welded steel mesh should be used. These are 6m x 2.4m sheets of 7mm welded steel into 15cm squares

- The diagram above shows shows that technically you only need one layer of ST25C, as long as it is placed in the bottom third of the slab on the parameter and in the top third in the middle. In reality, this is difficult in practice, so I plan to place two layers of ST25C, one in the bottom third and one in the top third

- Any joints between welded mesh should overlap 30 times the diameter of of the steel. I will be going for at least 30cm overlap, or three welds, to be sure

- Two horizontal reinforcements of 8mm steel should be place in every row, one on the inside and one on the outside; making sure that any steel remains greater than 30mm from the surface

- The vertical reinforcement in the walls should be in every cell of the block (25cm in my case) and be of 8mm

- The walls and slab should be connected using reinforced steel, bent into an L-Shape, of at least 50cm x 50cm

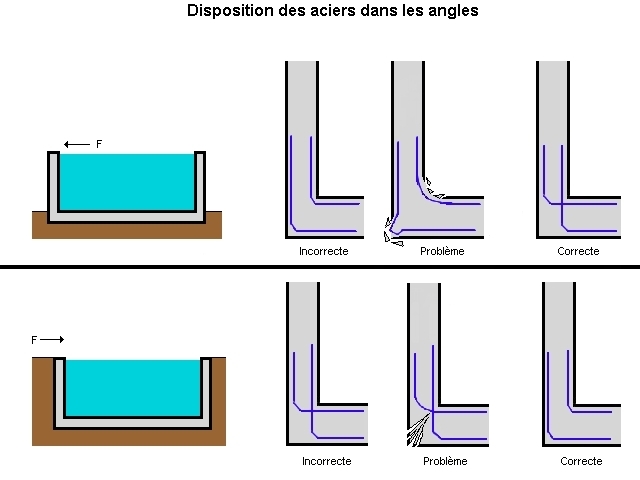

- The correct placement of the L-Shaped connectors is dependent upon where the forces will occur, with the main effect being if the pool is above or in-ground. I will be placing the angles towards the outside of the wall, as our pool is an in-ground pool and will experience pressure from the surrounding earth (as illustrated in the diagrams below)